Flush, Concave, V, Weather, Struck, Raked, Beaded, Grapevine. No, it’s not a Phonetic alphabet code, so tell Grandpa to put the Colt 1911 back between the mattresses. These are names of different types of mortar joints – Flush and Concave being the most common styles. The BrickWood Box Installation Manual recommends and uses 1/8” mortar joints in all of our CAD drawings, but try to stay within the 1/8” – 1/4” thickness (there this no thickness for Butt joints). 3/8” joints are pretty darn thick – the thickness of the joint tends to distract from the beauty of the veneer, so we don’t recommend that thickness. For added character, mix the veneer joints on the Upper and Lower Ovens. For example, you can have Butt Joints on the Upper Oven veneer and 1/4" joints on the Lower Oven veneer.

BUTT JOINT – All of the focus is on the veneer as there are NO visible mortar joints between the veneer.

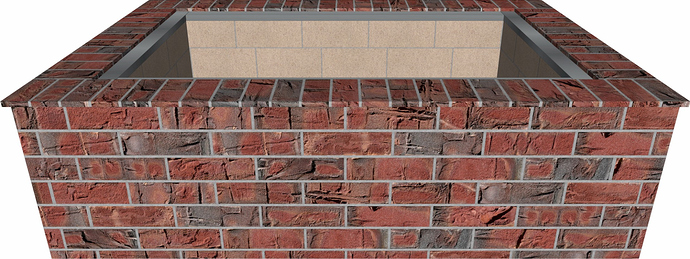

1/8” MORTAR JOINT – Show off the veneer, not the mortar. 1/8” joints are the suggested mortar thickness.

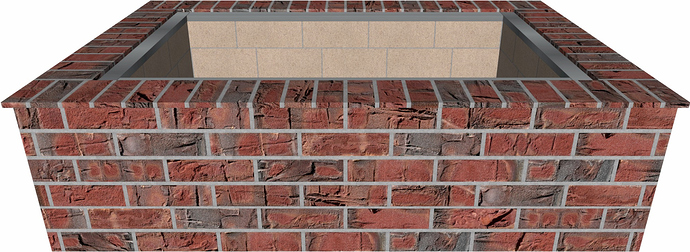

1/4" MORTAR JOINT – The thickness of this mortar joint is just a hair thicker than a pencil or pen.

3/8” MORTAR JOINT – Thick and obtrusive, this sliced bread-width joint is more for cinderblock walls.