Quick question, I’m getting ready to finish with a Ceramic blanket insulation And chicken wire to hold it on, I have heard that you can use Portland cement and perlite for the first two coats. And then after that finish and then with stucco. Is that the best way to go?

Best way to go… or another way to go.

2 or 3 layers of blanket will provide enough heat retention that additional exterior insulation would not be necessary.

That being said… You can do 2 coats of perlite / cement and a coat of stucco… but it might be a lot of work to retain a tiny bit of heat.

My one recommendation for heat retention is to purchase an additional box of blanket and wrap your oven w/ (1) additional layer.

Thanks for the info. I have a couple more questions, I have never done stucco before, I think I can do it, what particular products do you recommend for the Stucco, I am going to at least put three coats and paint at the end. And the next question,

I have seen some people has put a small Vent between them ceramic insulation all the way through the stucco to the outside, is that really necessary does it need to breathe?I have never built anything like this, first time pouring footers, Laying blocks, bricks,

The interior of my oven is 45 inches cooking surface.

Hi Jerry,

“Stucco” is a mystery to lots of us because we imagine houses sided with these beautiful stucco finishes applied by high priests of masonry. ![]() Neither the material nor the process is all that difficult, especially since you’ve been working with concrete and mortar all this time!

Neither the material nor the process is all that difficult, especially since you’ve been working with concrete and mortar all this time!

You can make stucco yourself using the instructions in this post. Cheap, and just requires a mixing tub and a hoe.

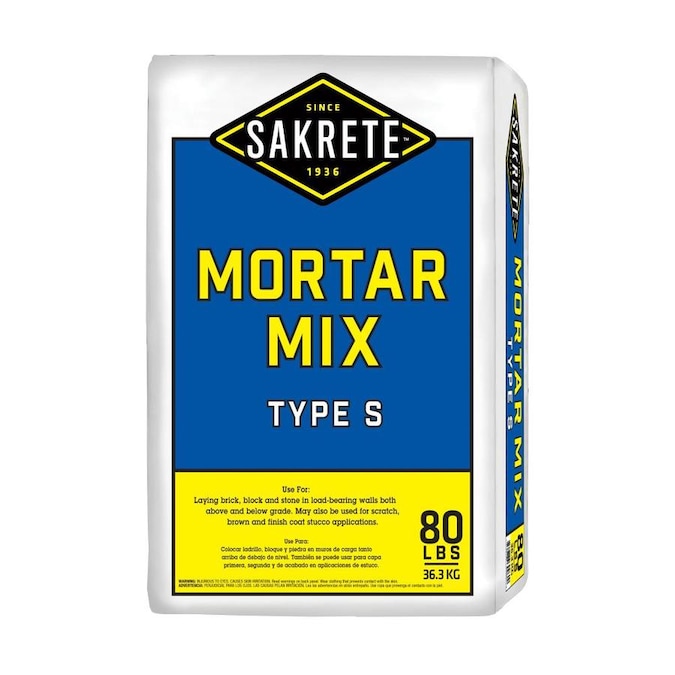

Next-cheapest (and the way I do it) is to purchase some mortar mix. I used Sakrete Type S, which is a high-strength mix of (wait for it) sand, hydrated lime, and Portland cement. If you look at this product photo you’ll see it is suitable for both scratch and finish stucco coats.

If you can locate a true stucco mix (which has reinforcing fibers mixed in with the three main ingredients), that’s also a possibility. As one builder discovered, there are different mixes sold for the scratch and finish coats.

I can speak to the Type S mortar application: when you mix it, you are going to need a much looser mix than the manufacturer calls for. You don’t want it so wet that it becomes “soupy,” but you don’t want stiff little balls of material either. In a mixing tray, put in about half of an 80 pound bag, then water in the middle. Mix until you have a wet, plastic mixture that makes that great “shoop-shoop” sound as you work it with the hoe.

You’d be wise to use a pool trowel to apply the mixture. Start at the top, then work down each side. Work the mix over the back and front edges. Do the front, up to but not covering the firebrick. The goal is to seal the insulation. Do the back. Make sure you run your trowel over the bottom edge all the way around. You’re not trying to achieve a perfectly smooth surface—in fact, your rough coat will have bits of chicken wire sticking through it and it will look pretty awful. Your finish coat will look better but still not perfect.

This is a pool trowel—less than $20

That’s when you use your utility sponge. Fill a 5 gallon bucket with water, get the sponge wet and wring it out, then work over your wet stucco with the sponge. It’s like a magic eraser: it will smooth the surface, draw away some of the Portland cement and leave sand behind, and generally make you feel better about the whole thing. ![]()

A $3 utility sponge will give you a million dollar finish

As for the vent: I suppose you could. But your fiber ceramic is directly touching the firebrick, which will absorb moisture. Once the oven is cured, it should not be an issue, and it strikes me as a way for moisture to get in as well as exit.

Good luck Jerry!