Once the stucco stage is completed I’m enclosing entire oven in a framed structure with metal roof. I’m planning on placing a 36" x 36" flat steel plate covering the entire front of the oven structure, cutting out a rectangular opening in the plate for accessing the cooking area. This would have an effect of reducing and customizing the size of the arch opening. Questions that are popping up: What adhesive to use to attach steel plate to firebrick or stucco? Is there a heat retention benefit with the steel front? Can you see any downsides to the steel front, ie. warping, heat conductivity, etc.? I’m thinking I may even be able to fabricate some sort of sliding/retracting steel door cover to completely close oven front for heat retention. The final look of the structure will be a bit “modern industrial”. Thanks for any comments and thoughts.

Hi GV, and welcome to the BrickWood forum.

Man, you have no idea how a post like this excites me! Hope you’re taking lots of photos of your build.

I think your questions about heat retention and warping all depend on the gauge of the plate; I’d be paying attention to make sure you don’t stoke and retain a fire that causes damage to your oven interior. And overall, you need to pay perhaps more attention to the principle of starting your fires “low and slow” to allow for heat expansion in both the steel and the brick.

So, a couple of thoughts:

- As long as you’re fabricating the plate, you might consider welding 4 1½ inch long and ⅛ inch diameter steel pins at locations along the edge, drilling holes into the firebrick arch (not the stucco) and fastening the pins in place using an industrial high-temp adhesive. I believe the holding power would be superior to simply “ess-ing” lines of adhesive flat over the brick and plate.

- I’m not sure I’d go along with the idea of a sliding or retracting door in channels on the plate. It may be I’m just more accustomed to the benefits of a free-standing door, but it seems like you’d be introducing some complexity there that may be more trouble than it’s worth.

Would love to hear other opinions from folks who have done something like this. We have a number of fabricators on the BrickWood forums.

Good luck with your build and let us see what you’re doing via photos when you can!

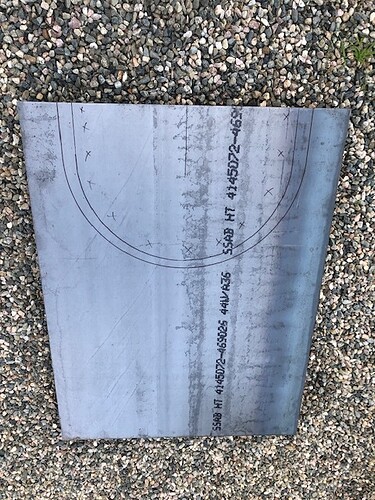

I made this plate to close off front when starting fire to keep the smoke from coming out the front instead of going up the chimney

Would you say it was effective, and did it extend the time needed to heat the oven up?

Finished 2nd stucco coat, insulated the chimney brick. Next step will be to frame the back and side walls and place the roof beams followed by cutting out the desired opening from the 36" x 48" x 1/4" sheet metal.

Framed sides, back and put up 2 of the 3 beams; cut out the steel plate using the barile grande door as a template less an inch. Next will make an extension for the rod coming out of the damper so that it will poke out of the steel plate.

This is really taking shape! Knowing from experience how much those beams can weigh, how did you get them hoisted and into place?

@BrickWood is really going to enjoy these photos. I know I am!

An old mini-excavator was used to strap the center point of the front beam to the bucket. It was then maneuvered behind the front posts. It’s height limit had been reached but we could place one end on the post cutout and then had to muscle the other end up about 6 inches. It was quite a challenge but no adversity is too great when it comes to decking out a pizza oven! Now moving on to paneling, preparing the roof, metal work and more. The project has become a monster but one step at a time will get this to an amazing end.

You’ve said a mouthful. Or a slice worth’s.

I’m inspired!

Roof over pizza oven is coming together nicely. Getting closer to forming and pouring a concrete bar.

Metal roofing on. Stone work progressing. Bar countertop formed and poured. Water, electrical and lights all hooked up and working. Looking to start the grill build soon.

This whole design is so well suited to the surrounding area. I think you’ve been very sensitive to how this build complements the natural environment. Needless to say, your stonework is impeccable.

Used for startup to keep smoke going up the chimney. Haven’t tried it yet, had back surgery so haven’t had a chance. Hopefully this week. I’ll let you know how it works.

Thanks for sharing the photo, Dale. I was wondering what had become of your project, and hope the surgery is bringing relief for your back! Looking forward to knowing how the new door works out for you.

Thought I’d make a few observations now that I’m just about done with the pizza oven project. The optional door is a “must have” and is used to direct the fire smoke up the chimney instead of out the front. Most of the heavy smoke is from the initial fire starting and if I place the door about an inch or so in front of the oven opening once I’ve started the fire, it works well at directing the smoke up and not out of the front opening. The temperature gauge, if you put one in the door, doesn’t really tell you much about the interior heat of the oven as you are bringing it up to the baking temperature so it looks good but doesn’t really serve a function for baking pizzas. I’m storing the baking utensils on the leeward side of the covering structure and that seems to be a good place for them. We brought water and electricity to the covering structure and I’m very glad we did. Peace of mind for the water and any fire danger, and the electricity allows for lighting and power and keeps extension cords away. The front overhang of the structure allowed me to put a large pull down projector screen and a sound bar out of the weather elements and leave them there. We’ve had a couple of pizza parties already and the pizzas came out fantastic right from the very first (probably lucky not to have burned any since it is remarkable at just how a pizza bakes in 2 or 3 minutes)! We use seasoned aspen for the firewood and it is burning beautifully. We are baking two pizzas side by side and were able to bake seven total pizzas without having to stop and reheat the baking surface. We’re hosting a wedding in a week or so and will be baking for 40 to 50 people! It will be chaos but a lot of fun for everyone.

Thank you Brickwood Ovens! Your products are fantastic and I encourage anyone thinking about building a pizza oven to become another very happy DIY customer. I’m happy to share my experience in building my oven with anyone but… “bikerbudmatt” is the encyclopedia britannica for information! …and the forum is great for answering a lot of questions.