I just had our oven built by a local masonry contractor last week. When I was re-reading the instructions today I noticed it specifically says not to use any mortar on the firebricks that are used as the cooking surface. I double checked and he did fill between the bricks with mortar. What kind of issues is this going to cause?

No worries! While it isn’t ideal… it will be fine.

One of the main reasons you don’t want to mortar in the hearth brick - replacing broken firebrick.

BUT - this rarely, rarely happens, so no stress.

In addition - you will have wood ash and pizza guts all over that brick & mortar very soon, so… you will hardly see the mortar in a few months.

That’s a relief…was a little stressed when I read that…Thanks for the reply. The guy did a really nice job overall.

Your guy did an EXCELLENT JOB!

Please be sure to send pictures to the BrickWood Ovens Photo & Video Gallery…

We would love to show your oven to the world!

Thanks -

We are in the rainy NorthWest, so we are pretty up-to-date on the best weatherproofing methods… especially on a budget.

The BEST way to weatherproof your oven (which we recommend to everyone) is to simply cover the oven with a thick, clear piece of plastic sheeting. This can be purchased at most Mom & Pop / local hardware stores - for about $10.

That’s about as budget-conscience and weatherproof as it gets. It keeps all the moisture out - nice and dry inside.

To the second part of your question - Applying several layers of paint on the stucco is an excellent way to seal a portion of the oven, but keep in mind, as long as there is exposed masonry, there is an opening for moisture. If masonry gets wet, it will act like a sponge and soak-up the water (wicking).

So unless you can afford a custom made cover for your oven (every BrickWood Oven is different - so we don’t offer covers), plastic sheeting is the best and least expensive way to weatherproof your oven.

wait- hang on?!

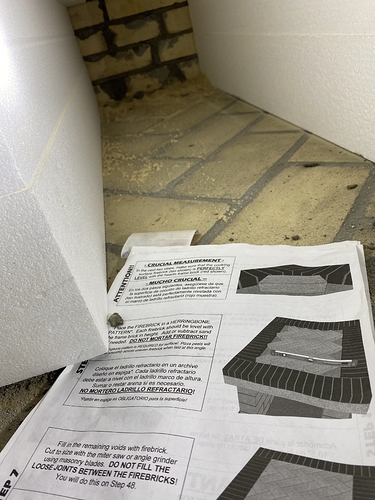

In another post @BrickWood suggests that this is a bigger problem. Also the above picture was used in a “what did they do wrong” picture hunt game. In that other post, it was suggested that when bricks get to 1200 degrees, something expands and something’s gotta give so the bricks might crack. Is that true - of course I’m on here worried because I’m in the same boat as the other guy. My mason that I hired mortared the bricks (but in herringbone, at least!). He’s not quite done with the firebricks of the wall so I am on here to see if I need him to tear down what’s been done to start the oven over.

Just to clarify - Your mason mortared the hearth firebrick base slab?

It’s not the best place to put mortar - those hearth firebrick need to move around. If they are mortared in, cracking will occur AND you run a good risk of getting mortar in your food. It’s just sand bonded together w/ other minerals… and that sand will get in your food.

yes - that’s what had happened. great news, and many thanks to this forum. his crew hadn’t fully completed the dome, yet. i got on here two nights ago, read through old posts about how wrong this was (mortaring down the hearth bricks), and talked yesterday morning with the mason. he said he’d read the instructions but thought he could make it stronger by mortaring. i’m happy to include that he took it all down, started over, and now it looks like this: (see picture of it being perfect)