Hi, I may want to change the design of the base ever so slightly. Are the split (half thick) firebricks ok to use instead of the full thickness bricks? This is for the cooking surface only. i do not want to have any heat issues when cooking the pizza.

I am trying to keep my height down on the cooking surface and hearth for a certain design (aesthetic) look that i am going for so essential the top surface of the hearth can be sanded down with exposed stone and glass pieces etc, whereas the design shows to add brick on top of the hearth. Or can I increase the insulating layer (vermiculite/portland cement) from 2 inch to 3 inch to make up any differences. this is still a 5inch hearth slab. thanks.

Hi Tim, and welcome to the BrickWood forum.

I believe you should not use splits for the hearth, even if you are planning to cover the brick. The firebrick surface does not insulate the hearth; it refracts the heat back up into whatever you’re cooking.

One other possibility is to recess the insulated slab a bit further. You could do this by adding and gluing an additional layer of closed-cell foam over the 2 inch piece called for. I would not recess it more than another inch, and frankly I feel the jitters coming on even as I say this.

You have something very particular in mind, so I’m going to call in “the ref” here (that would be @BrickWood) for another opinion.

I’m intrigued by what you’re picturing, though!

To expand on what @bikerbudmatt posted, think of the cooking surface firebricks as “heat storage”. If you shrink the size of the bricks, you reduce the amount of heat energy you can store in the cooking surface of the oven, and thus severely limit the cooking possibilities.

If you were building just for show, and never intended to use the oven yourself, I’d say go ahead and use the splits, but if you intend to cook with it (and I hope you do), use the full size bricks, and instead, use half-height blocks, or a pair of cap blocks for the top course of the base.

2 Likes

This does sound interesting…

Can you send a few pics of the area you want to install the oven -

And a sketch / design of what you have in mind for the oven?

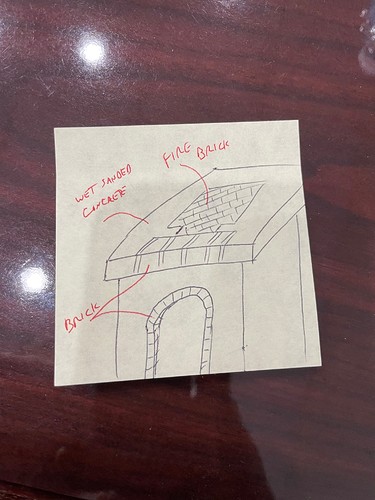

Nothing fancy… just a napkin sketch.

Thanks -

@bikerbudmatt @BrickWood @gdiscenza

All, first thanks off for taking interest in what i am doing and the advice so far. Here is a pic of what i am thinking… i made some concrete countertops for my garage a few years back and included some glass pieces and stone that all got polished down. it came out pretty good. i also colored the concrete dark gray too. my thought is to do similar with this hearth, instead of lining the entire top surface with brick. (fyi, my cinderblock base is already laid. next step is the hearth)

i MAY be able to some bricks from my grandpops old house where he and my dad and uncles built an outdoor stove many years ago. if i can get my hands on at least some of those bricks, i would like to line the front row of the hearth, but have them recessed into the concrete. . thus the reason to have the cooking surface as recessed into the hearth as possible.

i do plan to use this pizza oven for cooking and fun with the kids. fyi… this would be 4 generations of family use out of those bricks (if i can get them). also, i tried to get some technical info out of firerock on their bricks (split vs full) but did not really get anything useful.

hope this was not too wordy… just trying to get the details out there. thanks again in advance!

That sketch helps a lot. We’re talking about two sets of bricks: the framing bricks (which you are looking to replace at least partially with wet sanded concrete and glass) and the hearth bricks, which as I understand it you want to recess an inch or so into the hearth.

I’m wondering if dropping the height on the framing bricks by laying them on their bases rather than their sides; completing the frame with the sanded concrete; and either maintaining the spec’ed height for the hearth bricks or dropping them an inch into the slab — would that do what you’re looking for?

We’ll possibly go a few rounds on this to understand completely what you’re going for, but is that closer to what you have in mind?

1 Like

yes you are on the right track for what i am thinking. im wondering if i should make a recess where the hearth bricks would go to make it level or close to level with the fire rock brick cooking surface. and recessing the insulted slab down to 3 inch like you mentioned earlier. ill have to find the dimms of the fire rock bricks and the bricks i may be using and see how how much higher they would be compared to the concrete hearth.

2 Likes

I would suggest instead to increase the height of the hearth slab to just a bit taller than what the combination of concrete and brick would be in the original @BrickWood designs. You would maintain a recess in the center for the sand/firebrick cooking surface, and have a bit of concrete available to grind back for the polished look you are after. I don’t know if you could do this with the sectional pour that the instructions specify, but with the right framing, you could pour the concrete in place.

2 Likes

Increasing the height of the slab i think, will be a great idea. i already made my forms but it wont take much to extend them another inch or so and secure them prior to the pour. i think what i have to now is see if i can get those “heirloom” bricks and get the dimensions. they are really the basis of the design.

2 Likes

Hi all,

I know I’m late to the subject but hear is my two cents. I see everyones point on using full size bricks for the hearth. Retention of heat and radiant heat as well.

But I can say this. I used splits for my hearth cooking surface. Reason being is that the brick yard where I got the said they where rated for 2000 degrees. I had two manufacturers to choose from. One, the edges where not crisp and could have some minor chips. But where less expensive then the other manufacturer that had crisp and really square edges.

So I used the lesser cost full size bricks for the arch and the niceer more expensive split bricks for the cooking surface because I wanted my peel to glide with ease. Let me tell you the split bricks has not effected the performance of the oven.

As far as raising the base? I don’t know. Thats personal preference. My wife is shorter than me and reminds me of that every time the oven is in use and she has to get on a stool.

Happy building!

1 Like

Hey Pete, thanks for adding that experience! It’s good that you haven’t felt affected by having the split bricks in the hearth.

And I trust you’re baking up a storm now!

Hey Matt,

Yes been using the oven alot. It out performs itself every time. My neighbors roommates who are from Italy throw parties and request my pizzas because they can’t find neapolitan pizza like they get back home. I cooked other dishes like chicken, turkeys, bread, and steak.

I just got a custom door made it so I’m hoping baking other dishes using the retention of heat.

1 Like

I remember you said something about that custom door when we were talking about the winter wet blues—you built an enclosure for your oven as I recall. Would love to see photos of your work when you get a chance.

As for the neighbors from Italy…it is really, truly difficult to get an excellent Neapolitan crust pizza in a pizzeria. I live in the greater New Haven, Connecticut area and we are so, um, blessed with pizza houses. But a pizza restaurant has to pay attention to ingredient costs, customer tastes, and “guaranteed success” (a term I just made up that means every pie you put into your oven has to come out the first time, and be acceptable for table or takeout service).

Around here, I can’t name a pizzeria without starting an argument, and it’s just sacrilegious to say that none of them are truly excellent. (Actually, a couple of them are, but as I said, can’t name one…)

But at home, I can easily bake a pizza that brings tears to the eyes because I don’t have to add any ingredients that guarantee success but bring down quality. Having a hot wood-fired oven makes it that much better.

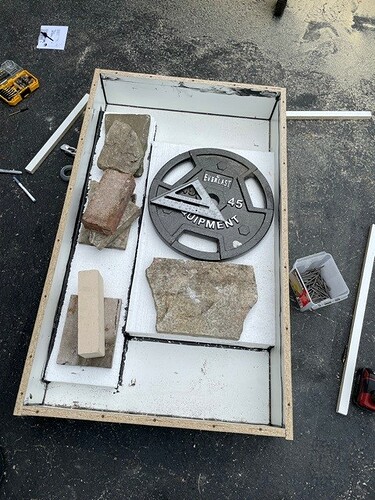

I got the forms in place this weekend and started the build!! boy, they were heavy. prob 500lbs each. here are some pics if interested… this is fun work but hard work. lol needless to say it is gaining a lot of interest from the neighbors.

2 Likes